Piston Pump Spare Parts: Enhancing Performance and Longevity

Piston pumps are vital components in many industrial applications, especially where fluid delivery is essential. These pumps are renowned for their efficiency and reliability, but like all mechanical systems, they require regular maintenance and replacement of parts to ensure optimal operation. This article delves into piston pump spare parts, exploring their significance, factors to consider when purchasing them, and how they contribute to the overall performance of diesel engines.

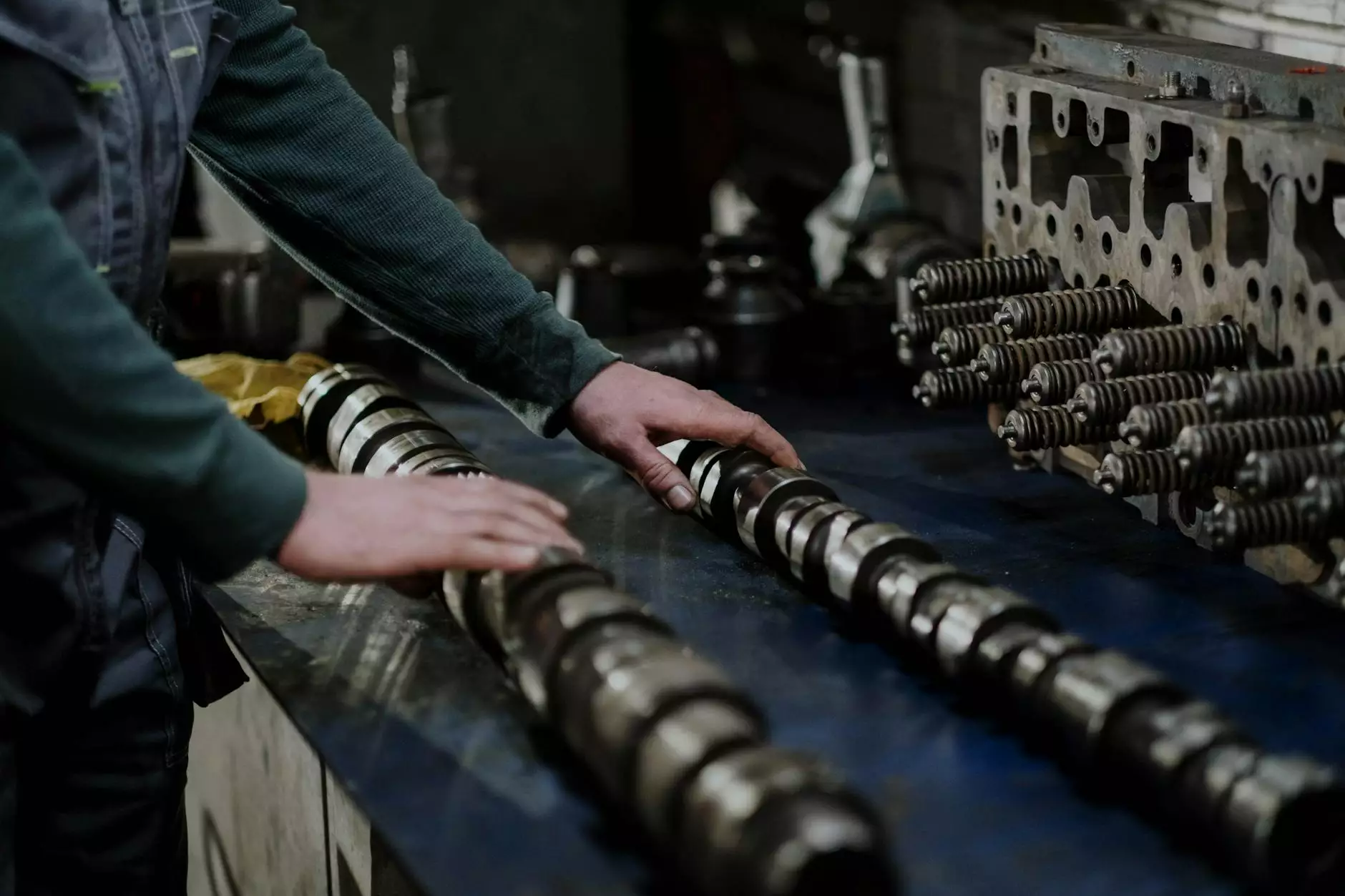

Understanding Piston Pumps

Piston pumps utilize a reciprocating mechanism where the piston moves back and forth within a cylinder, creating a vacuum that draws fluid into the chamber and subsequently expels it under high pressure. This operation is crucial in a variety of applications, from hydraulic systems to fuel delivery in diesel engines.

The Role of Spare Parts

Given the rigorous demands placed on piston pumps, it is inevitable that some components will wear out over time. Spare parts are crucial for several reasons:

- Maintaining Efficiency: Worn parts can lead to decreased efficiency, causing the pump to work harder and possibly consume more energy.

- Preventing Mechanical Failures: Regular replacement of worn-out parts can prevent catastrophic failures that could halt operations.

- Ensuring Safety: Faulty pumps can pose safety risks, especially in industrial environments where fluids may be hazardous.

- Extending the Pump's Lifespan: Using quality replacement parts can significantly extend the lifespan of your piston pump.

Types of Piston Pump Spare Parts

When it comes to piston pump spare parts, several components may need to be replaced over time. Understanding each part and its function helps in making informed purchasing decisions:

1. Pistons

Pistons are the heart of the pump. They must be durable and resistant to wear. Many high-performance pistons are made from hardwearing materials to withstand pressure and friction.

2. Cylinders

Cylinders house the piston. Any wear or tear in the cylinder can lead to decreased efficiency and pumping capacity. Choosing a robust cylinder material is vital.

3. Seals and O-Rings

Seals and O-rings prevent leakage and maintain pressure within the pump. These components are often the first to wear out, making regular inspection and replacement essential.

4. Valves

Check valves ensure that the fluid flows in the correct direction. They need to operate reliably to maintain efficient pump performance.

5. Rods and Connectors

The connecting rods and components must maintain integrity to ensure efficient movement of the pistons. Any wear can lead to performance issues.

Choosing the Right Piston Pump Spare Parts

Selecting the correct spare parts for your piston pump can significantly affect its performance and longevity. Here are some considerations to keep in mind:

1. Compatibility

Ensure that the spare parts you purchase are compatible with your specific pump model. Using incompatible parts can lead to inefficiency and damage.

2. Quality

Investing in high-quality parts is essential. Inferior spare parts can lead to frequent replacements and additional costs in the long run.

3. Supplier Reputation

When purchasing piston pump spare parts, consider the supplier’s reputation. Trusted suppliers often provide warranties and have robust customer support systems in place.

4. Pricing

Compare prices from multiple suppliers. While the cheapest option might seem appealing, it’s vital to balance cost with quality and durability.

5. Customer Reviews

Look for customer feedback and reviews about specific parts and suppliers. This can give insights into the reliability and performance of the parts.

The Importance of Regular Maintenance

A well-maintained piston pump is crucial for maximizing efficiency and performance. Here are some key maintenance tips:

- Routine Inspections: Regularly check the condition of all parts, paying close attention to seals, valves, and the condition of the pistons.

- Lubrication: Ensure that parts are adequately lubricated to minimize friction and wear.

- Cleaning: Keep the pump and its components clean to prevent contaminants from causing damage.

- Timely Replacements: Replace any worn or damaged parts immediately to avoid further complications.

Conclusion: The Future of Piston Pump Spare Parts

As technology advances, the quality and availability of piston pump spare parts continue to improve. Suppliers like client-diesel.com offer a wide range of high-quality parts tailored for various industrial applications, ensuring that businesses can maintain their equipment with ease.

By understanding the importance of these components, the types available, and how to select the best options, businesses can enhance their operational efficiency and reduce downtime. Investing in quality piston pump spare parts not only ensures reliable performance but also fosters a safer work environment, ultimately contributing to the overall success of your operations.

For more information on obtaining quality piston pump spare parts and ensuring the longevity of your diesel engines, visit client-diesel.com.